Instrumentation

RMS offers custom instrumentation services to fit your applications and specifications

When you are looking to measure strain on your vehicle or structure, Remote Mechanical Sensing (RMS) is there to instrument your mechanical parts with strain gauges. Thanks to our solid experience using custom gauges, we offer our services for a wide array of applications in various fields going from Motorsport to Aeronautics, Military and Medical, to name a few.

Our 3-step process:

- Strain gauge bonding

- We perform an accurate and thorough bonding of custom strain gauges to ensure maximum reliability and precise measurement of each strain point - Test bench data acquisition

- We measure and collect data during our test phase: force, deformation, temperature - Data analysis

- We process & analyze the collected data and then display test reports on our datasheets

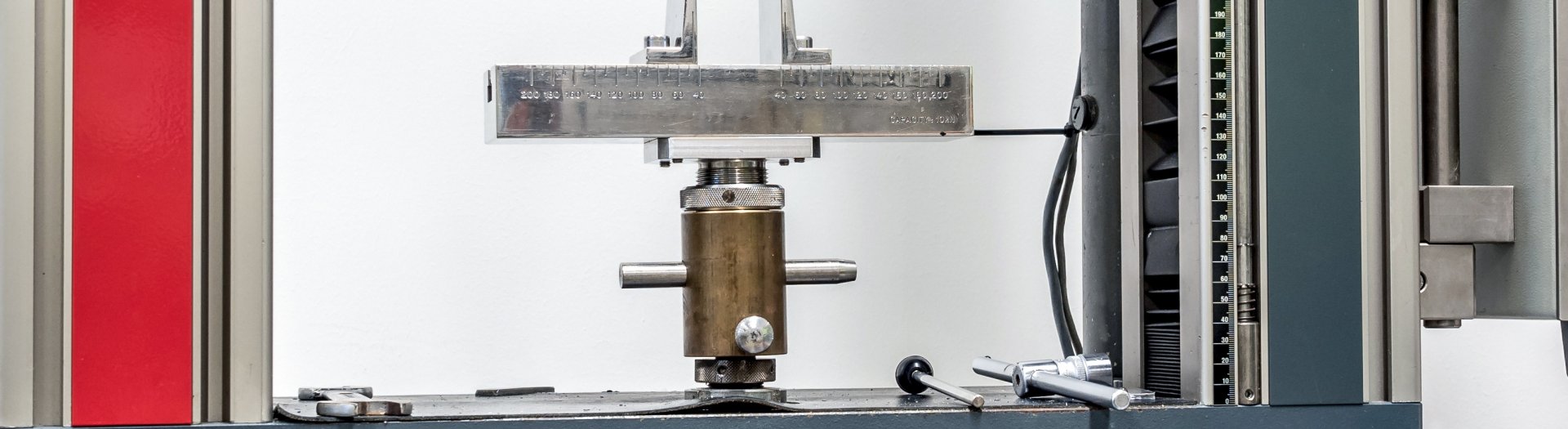

Calibration and testing

RMS provides calibration services for force & torque as well as thermal compensation

Remote Mechanical Sensing (RMS) provides services for tension, compression, flexion, and torque. As experts in strain gauging services, calibration and testing is an essential part of our process. When using strain gauges, temperature variations typically have an unfavorable impact on the measurement outcome. This is the reason why we always ensure each instrumented part goes through thermal compensation tests before undergoing calibration & further tests for data analysis.

Our Services include

- Preparation of the part for a perfect surface in order to fit the strain gauge

- Full installation of complete bridge

- Temperature compensation (at low level) up to 180°F for no signal drift under high temperature

- Fitting of analog & digital amplifier for 0-5V output

- Calibration using the Instron machine and spec sheet provided